Have you ever wondered how fastener packaging is manufactured? What about materials, production steps and quality control? This article will answer all of these questions and show how a reliable paper packaging company produces carton boxes for fasteners (screws, nuts, bolts…).

Which materials are suitable for fastener packaging?

The first step in the screw box manufacturing process is to choose materials from a reputable source. A reliable paper packaging company will use high-quality cartons and corrugated to ensure the strength and rigidity of the box. In addition, based on customer requirements, cardboard boxes may need to meet FSC standards and some other certifications. Therefore, choosing suitable materials is an extremely important operation.

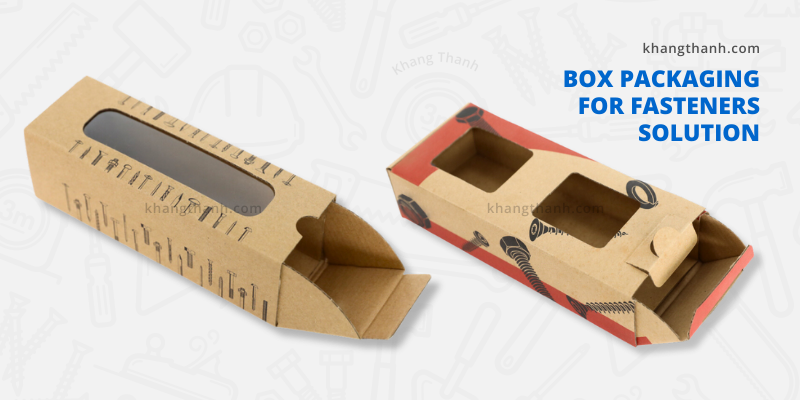

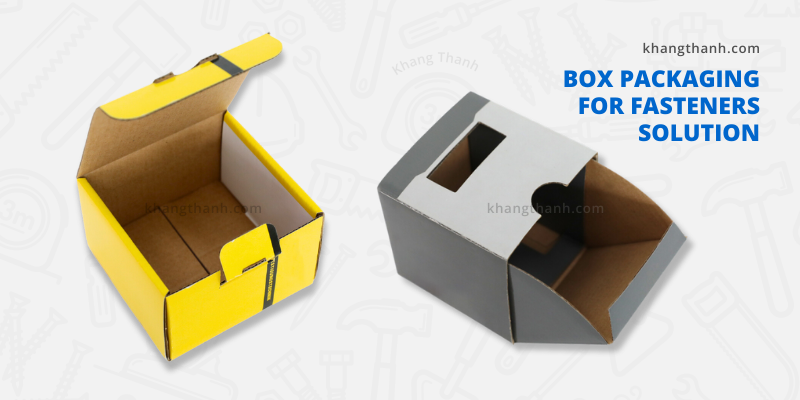

Because of the specific nature of the fastener industry, the design of the carton box is quite simple. The box is usually just laminated with a glossy or matte film without any printing effect. Besides, accessories such as plastic windows can also be added to facilitate viewing of the fastener inside.

>>> Experience in determining the moisture of the carton packaging

Discover the production steps of fastener packaging

After selecting the materials, the paper packaging company will carry out the production process of the screw carton box. The basic process includes the following steps:

- Prepress section: The prepress team will design the structure and artwork files for the next production steps. Besides, essential factors including size, shape, colour, and printing information, also need to be agreed upon at this stage. Because if you change at the following steps, it will be difficult to edit and lead to expensive costs.

- Printing: After prepress, the printing process will be done. The paper packaging company will use advanced printing technologies to ensure the colour accuracy and sharpness of the images and the information on the box.

- Laminating and die-cutting: Next, the cartons are laminated and die-cut into shapes according to customer requirements. This process requires a high level of engineering to ensure accuracy and avoid wave breaks and damage.

- Finishing section: Last but not least, if no lamination or additional accessories are added, the cardboard fastener box will be transferred to the finished product stage to perform the final.

- Laminating or glueing windows (if any): For some carton boxes containing screws that want to create accents, the company can perform additional steps of laminating or glueing windows. There are two common types of specialized membranes: glossy film and matte film. Therefore, customers can be flexible in choosing.

Ensuring quality and transporting

After the production process is completed, the fastener boxes are put into the finished section and delivery stage. A reputable paper packaging company will have its own Quality Control (QC) department to check the quality of the finished product, as well as the porosity, compression, and moisture of the cardboard box must meet the standards before delivering to customers.

Besides, the screw carton boxes can be stored at the warehouse while waiting for the delivery schedule from the customer. Therefore, having a large, well-ventilated warehouse and ensuring fire safety will be a point to note that a reputable paper packaging company must meet.

In contrast, packaging companies will have their own delivery team to transport goods to customers’ warehouses in local or to ports for export purposes. Ensuring adequate facilities and qualified factories is a big criterion that you can use to evaluate a paper packaging company’s quality.

>>> Guidance on how to evaluate quality carton packaging

Thank to the simple design and printing section, the price of fastener packaging is affordable. Therefore, you only need to describe the idea and manage the production process to ensure the finished box is up to standard. Khang Thanh provides comprehensive packaging solutions for fastener packaging. Reaching out to us at:

KHANG THANH – HOUSE OF PACKAGING

Tel: 077 8878 222

Email: info@khangthanh.com