This article is a visual guide to a Vietnam rigid box factory, ideal for clients unable to travel. By showcasing real operations through photos from machinery to human teams, it builds trust and helps overseas partners assess quality and capacity from anywhere.

Factory overview

Khang Thanh owns 2 factories specializing in the production of rigid boxes in Dong Nai province with a total area of about 13,500 sqm will be capable of meeting large orders. In addition, each factory is equipped with a modern machinery system and a flexible operating process to ensure fast delivery without affecting quality.

Operating according to the Make-to-Order (MTO) model, Khang Thanh optimizes production costs by reducing inventory, minimizing waste and increasing space efficiency. Therefore, customers can easily customize according to their own needs while still controlling their budget and delivery time well.

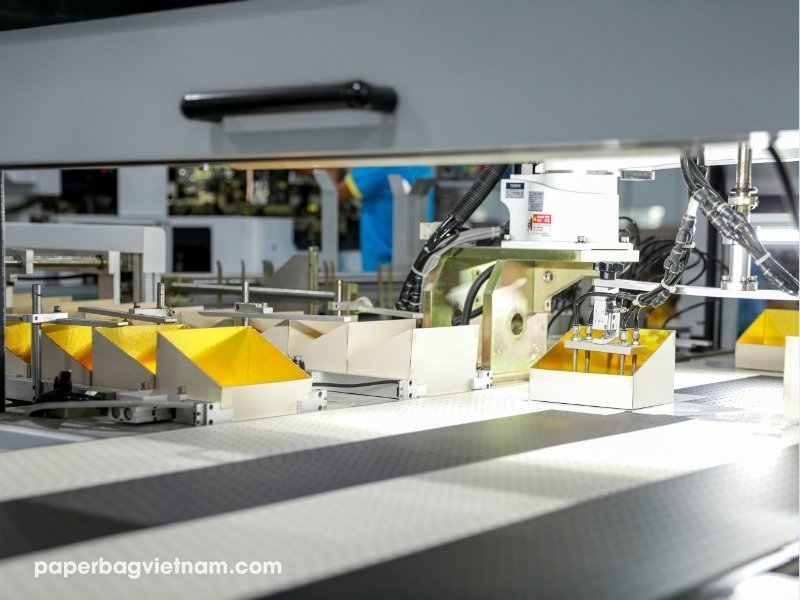

Process behind the final luxury box

The highlight of rigid box supplier is the automated production line reflecting the commitment to quality. Let’s take a detailed look inside through the production process that make up the premium box.

1. Offset Printing (Up to 8 Colors)

Start with offset printing from Japan, Germany. The offset printers are capable of printing from 3 to 8 colors with high precision.

Moreover, the process ensures consistent, sharp and high-resolution images. In particular, modern printers are key for rigid box manufacturers when printing large orders.

At this stage, rigid boxes is controlled through:

- Color calibration is strictly controlled

- Print alignment is checked regularly

- All printing stages are controlled by skilled technicians

Optimize your business efficiency with a reliable packaging supplier

2. Post-Print Processing

After printing, the sheets come to the finishing process to complete the final rigid boxes. This step includes surface effect processing and creating the finished premium box shape.

In particular, the luxury box is enhanced in hardness, durability and aesthetics through the post-printing stage by applying high-end effects below:

- Lamination: matte, gloss

- Foil stamping (gold, silver, hologram)

- Embossing, debossing

- Die cutting for precise structure

- Folding and gluing with automatic machines

3. Quality Control (QC)

The dedicated QC team at Khang Thanh adheres to ISO certified quality management systems to inspect the finished premium boxes to meet the standards before delivery.

In addition, the QC team also conducts drop tests, edge crush tests and moisture resistance tests to ensure the durability of the boxes, especially for export.

4. Customer Service

Merchandising department of rigid boxes supplier plays a connecting role throughout the entire ordering process. The workflow includes quotation, technical advice, order processing to the final delivery stage.

Moreover, with a bilingual communication team and rich experience working with multinational brands, customer care can flexibly handle specific requests according to each market, time zone and operating process of each business.

Additionally, after the order is completed, the Sales team continues to provide support. Staff will assist with any additional needs such as reorders, design adjustments, or handling customer feedback. This ensures long-term satisfaction and helps build lasting relationships with customers.

People behind the process

At Khang Thanh, our team transforms creative ideas into precise packaging by strictly following quality and safety standards. We also provide regular training programs to enhance skills and broaden knowledge in both professional and personal aspects.

Khang Thanh also prioritizes the mental health of employees through events such as Tet Party, Team Building, Women’s Day and birthdays.

These activities promote a positive, respectful and sustainable workplace. In addition, they help to nurture a dedicated team that provides professional packaging solutions.

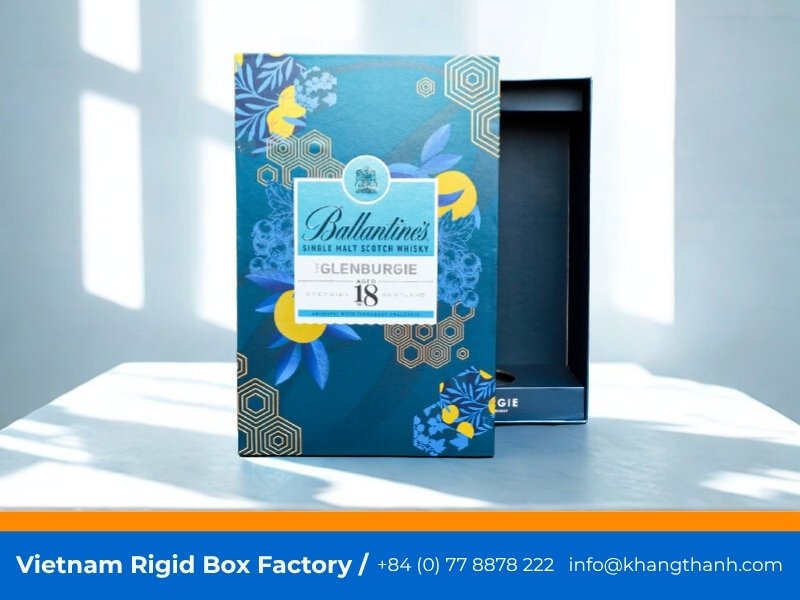

Global Clients and Projects

Khang Thanh is proud to serve a wide client portfolio across Europe, the United States, Japan, Korea and Australia, with a complete, fast and professional custom rigid packaging service.

Khang Thanh with global projects include:

- Manufacturing rigid cosmetic boxes for global brands

- Design, print and manufacture of wine boxes, premium rigid wine boxes

- Processing of premium leather wine boxes with exquisite details and high finishing

- Premium rigid gift boxes for businesses on special occasions

As a trusted Vietnam rigid box factory, we always puts the importance of confidentiality, quality and delivery time first. This gives customers peace of mind and complete trust.

Plan your visit to Khang Thanh’s factory

Want to see how the actual production process works? Khang Thanh has 2 rigid box factories in Vietnam and a customer care team ready to take appointments. Contacting us quickly via:

- Hotline: +84 (0)77 8878 222

- Email: info@khangthanh.com

In particular, both factories in Dong Nai are conveniently located, only 30km from Tan Son Nhat International Airport, international ports and neighboring provinces.

- Headoffice: Lot 103/6 Road 5, AMATA IP, Bien Hoa City, Dong Nai Province, Vietnam

- Factory: Lot 230 Road 4, AMATA IP, Bien Hoa City, Dong Nai Province, Vietnam

Why should choose premium gift box made in Vietnam?

Instead of choosing ready-made box models, brands will prefer to find a manufacturer who can design boxes according to their own requirements, accompanying the packaging from the idea to actual production.

Therefore, manufacturing rigid boxes in Vietnam is the perfect choice because:

- Competitive prices

- Skilled workers and attention to detail

- Reliable logistics services for global shipping

- Flexible in MOQ and customization

In particular, when cooperating with a rigid boxes supplier, customers will be guaranteed a comprehensive solution in terms of technique and aesthetic design. For global brands, this is very important because packaging will affect brand image, customer experience and revenue.

The photo tour marks the first step toward understanding what goes into premium packaging. At Khang Thanh, we integrate technology, processes, and people to create packaging that does more than protect—it connects.

Explore more with a reliable rigid box factory in Vietnam. Contact us to request samples, discuss custom solutions, or book a factory visit.

PAPER BAG VIETNAM

Tel: +84 (0) 77 8878 222

Email: info@khangthanh.com